Test robot

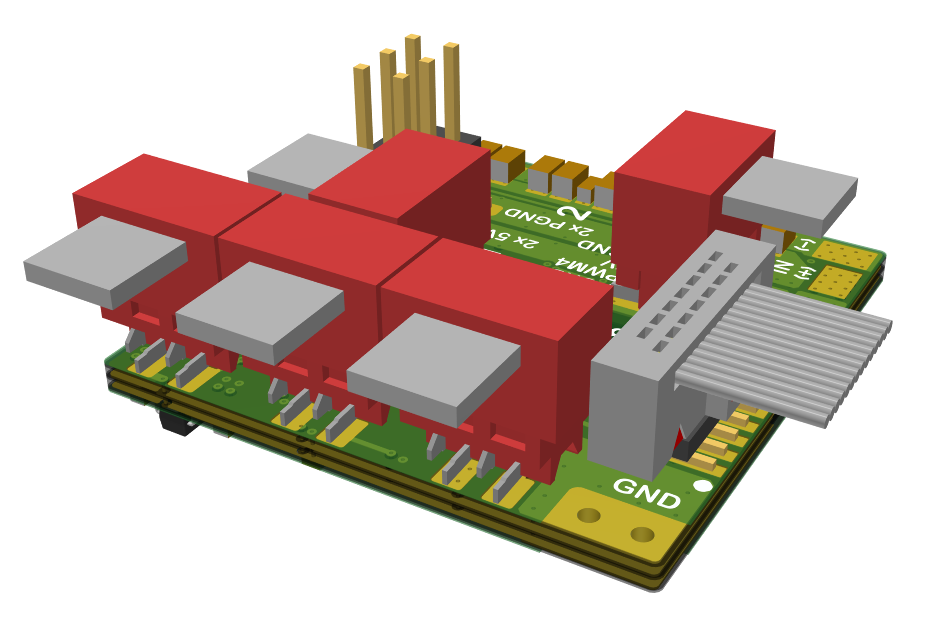

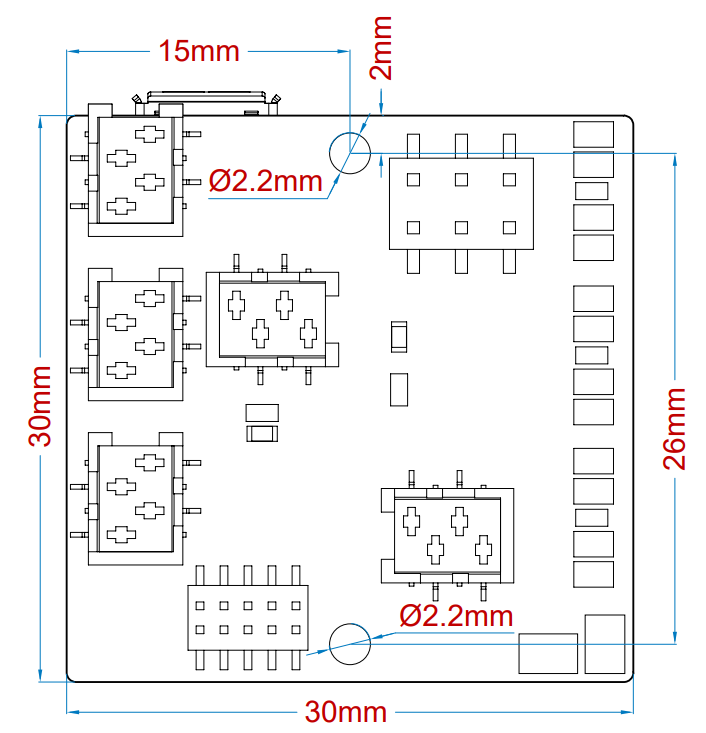

Mainboard

Functionality

-

Closed loop speed control of 3 brushless DC motors.

-

Designed for Pololu 37D Metal Gearmotors with quadrature encoders.

-

Motor driver current limited to 3.0 A.

-

Motor driver supply voltage up to around 16.8V (maximum voltage of 4S LiPo batteries). Limited by ceramic capacitors that are rated to 25 V.

-

-

Reverse voltage protection MOSFET on the motor driver supply side.

-

Two 5 V small hobby servo outputs with 50 Hz PWM signals.

-

One BLDC ESC (Electronic Speed Controller) signal output using DShot300 protocol.

-

Reverse voltage protected motor power output for thrower ESC.

-

Isolation between microcontroller and motor drivers.

-

STM32G441KBT6 microcontroller.

-

Powered through USB connector.

-

-

Micro-USB socket for communicating with a computer over virtual COM port.

-

Two ball detector inputs.

-

10-pin SWD (Serial Wire Debug) connector.

-

One UART interface with solderable pads.

-

Two M2 mounting holes.

Firmware

Binary firmware file

Connect STLINK programmer to the mainboard and to a computer with USB. Drag or copy the *.bin file to the STLINK drive.

Sending commands to mainboard

Struct in firmware

typedef struct __attribute__((packed)) Command {

int16_t speed1;

int16_t speed2;

int16_t speed3;

uint16_t throwerSpeed;

uint16_t servo1;

uint16_t servo2;

uint8_t disableFailsafe; // 1 to disable failsafe, anything else to enable

uint16_t delimiter;

} Command;Using with python’s struct library

disable_failsafe = 0

struct.pack('<hhhHHHBH', speed1, speed2, speed3, thrower_speed, servo1, servo2, disable_failsafe, 0xAAAA)Receiving data from mainboard

Struct in firmware

typedef struct __attribute__((packed)) Feedback {

int16_t speed1;

int16_t speed2;

int16_t speed3;

int16_t position1;

int16_t position2;

int16_t position3;

uint8_t sensors;

uint16_t delimiter;

} Feedback;Using with python’s struct library

actual_speed1, actual_speed2, actual_speed3, motor1_position, motor2_position, motor3_position, sensors, feedback_delimiter = struct.unpack('<hhhhhhBH', received_data)Thrower speeds

Thrower speeds are sent to thrower motor controller using DShot protocol. Speed values are between 48 - 2047 for 0 to 100% speed.